Lixea is ready to scale up the pulp process of the future to an industrial level

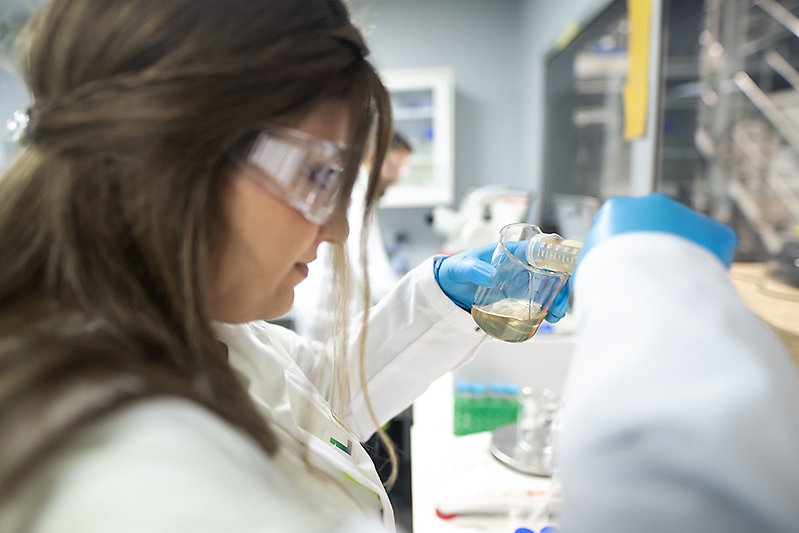

Lixea in Bäckhammar has developed an innovative technology that enables the sustainable use of the entire biomass – without strong chemicals or unnecessary energy consumption. Unlike traditional pulp processes, which focus on extracting cellulose, Lixea also separates lignin and hemicellulose using an ionic liquid (liquid salt). This provides pure raw materials for new fossil-free, sustainable materials and products instead of by-products with little value.

Marcus Elmer, Lixea

"Nature is amazing at creating biomass; vegetation thrives all over the globe," says Marcus Elmer, Chief Operating Officer and Commercial Manager for Lixea's pilot plant.

"Here in Scandinavia, we primarily think of raw materials from the forest, but the possibilities are much broader than that!"

He notes that the world's problem is not the lack of renewable resources, but that the raw materials vary so much and that methods to process them efficiently and sustainably have been lacking.

"We can use the same process to handle everything from straw, rice stalks, and fast-growing grasses to coniferous and deciduous wood, and utilize enormous amounts of agricultural residues," continues Marcus Elmer.

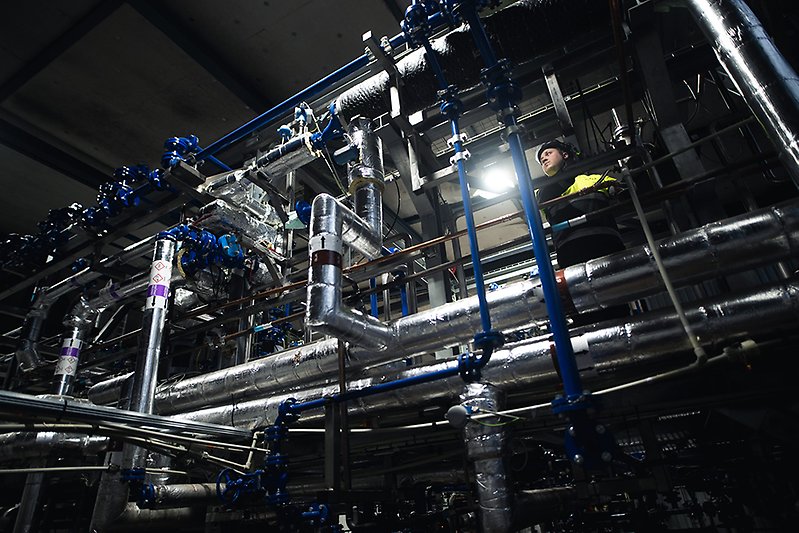

From London to Värmland

The development work started in a research lab at Imperial College London, one of the world's leading technical universities. Based on successful research results, the company was founded in 2017 by Dr. Florence Gschwend, Prof. Jason Hallett, and Dr. Agi Brandt-Talbot. The next goal was to test and gradually scale up the idea from a lab environment to real industrial conditions. A € 4.3 million EU grant made it possible to establish the pilot plant that was completed in Bäckhammar in Värmland county in 2022.

"In Värmland, there is unique expertise and long experience in the pulp and paper industry related to cellulose and lignin," says Marcus Elmer.

"By establishing Lixea's core operations here, we have quickly become part of a strong network of actors with global reach and gained access to existing infrastructure. The proximity to large companies like Stora Enso, Billerud, and Nordic Paper makes the region an ideal place to commercialize our technology."

"Help other actors replace fossil materials"

Today, the Lixea team consists of eight people who together bring the expertise needed to take the next steps in development. The CEO is Krisztina Kovacs-Schreiner, who moved to Värmland from the UK with the mission to establish the pilot plant and lead Lixea in its development from a startup to a growing company within the circular economy.

"At its core, our innovation is a platform technology that can be adapted to many different applications and can help other actors replace fossil materials with bio-based ones," says Marcus Elmer. "The unique aspect is that our pulp process works equally well regardless of the raw material, making it extremely flexible and scalable for a global market."

He explains that Lixea acts as a "spider in the web" between different actors and stakeholders by connecting those who have the raw material and want to refine it with companies interested in specific end products.

Great potential

"The cellulose we extract can be used for paper and cardboard, but also for textile fibers within an industry struggling with major environmental challenges. Pure cellulose is crucial for high-quality textile fibers, and this is very costly in existing value chains, giving us a valuable competitive advantage", says Marcus Elmer.

Lignin is an underutilized resource in the world – with great potential.

"The lignin we extract has a pure and usable form. Additionally, it is odorless. It can, among other things, replace oil-based polymers in plastics and is an alternative, fossil-free binder in asphalt. Glue manufacturers and battery manufacturers are examples of other target groups."

The next step for Lixea is to build an industrial plant that handles 25,000 tons of raw material per year. The financing is secured, and the plant will be built in Europe.

"Half of the year, the plant will process straw and other agricultural residues, and during the other half, forest raw materials," says Marcus Elmer. "When the plant is operational, it will become even clearer that our technology works on different types of biomass."

Värmland provides us with the right industrial environment to succeed

Lixea is the first company in the world to scale up a pulp process based on ionic liquids. Researchers around the world are following the development work with great interest. Study visits from both academia and industry are common here in Bäckhammar.

"It is exciting to follow such groundbreaking research all the way to the market for commercial production," says Marcus Elmer. "Värmland provides us with the right industrial environment to succeed. Here we have access to the right expertise, an international network of actors within the pulp and paper industry, and unique cutting-edge competence."

Lixea Sweden AB – Pilot Plant

Lixea is a development company scaling up a biorefinery process based on a recyclable solvent. The technology enables local production of cellulose, lignin, and platform chemicals without losses and waste streams, and can be used to reduce dependence on fossil raw materials.

Revenue: SEK 2 million (2023)

Establishment in Värmland: Bäckhammar

Number of employees: 8

Website: www.lixea.co